Diaphragm compressor wani nau'i ne na kwampreso na musamman wanda ke taka muhimmiyar rawa a fannoni da yawa tare da tsarinsa na musamman da ka'idar aiki.

1. Structural abun da ke ciki na diaphragm kwampreso

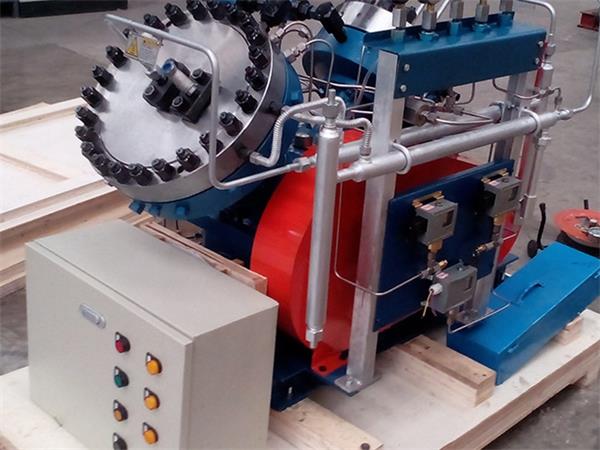

Compressor diaphragm galibi ya ƙunshi sassa masu zuwa:

1.1 Tsarin tuƙi

Yawanci ana yin amfani da injin lantarki ko injin konewa na ciki, ana isar da wutar zuwa madaidaicin kwampreso ta hanyar watsa bel, watsa kaya, ko haɗin kai tsaye. Ayyukan injin tuƙi shine samar da ingantaccen tushen wuta don kwampreso, tabbatar da cewa compressor na iya aiki akai-akai.

Misali, a wasu kananan kwampressors na diaphragm, ana iya amfani da injin mai hawa-guda guda daya a matsayin hanyar tuki, yayin da a cikin manyan kwampressors na masana'antu, ana iya amfani da manyan injina mai hawa uku ko injunan konewa na ciki.

1.2 Crankshaft haɗa sandar inji

Na'urar haɗa sandar crankshaft ɗaya ce daga cikin ainihin abubuwan da ke tattare da kwampreso diaphragm. Ya ƙunshi ƙugiya, sanda mai haɗawa, giciye, da sauransu, wanda ke canza motsin jujjuyawar injin tuƙi zuwa motsi na madaidaiciyar motsi na piston. Juyawa na crankshaft yana korar sanda mai haɗawa zuwa lilo, ta haka yana tura kan giciye don yin motsi mai maimaitawa a cikin faifan.

Misali, zane na crankshafts yawanci yana amfani da kayan ƙarfe masu ƙarfi masu ƙarfi waɗanda ke yin ingantattun injina da maganin zafi don tabbatar da suna da isasshen ƙarfi da taurin kai. An yi amfani da sandar haɗawa da kyawawan kayan ƙarfe na ƙirƙira, kuma ta hanyar daidaitaccen aiki da haɗuwa, yana tabbatar da haɗin gwiwa tare da crankshaft da crosshead.

1.3 Piston da Silinda jiki

Piston shine bangaren da ke hulɗar kai tsaye tare da iskar gas a cikin kwampreshin diaphragm, wanda ke yin motsi a cikin silinda don cimma matsawar gas. Jikin Silinda yawanci ana yin shi da ƙarfe mai ƙarfi ko simintin ƙarfe, wanda ke da kyakkyawan juriya. Ana amfani da hatimi tsakanin fistan da silinda don hana zubewar iskar gas.

Misali, saman fistan yawanci ana kula da shi da magunguna na musamman irin su chrome plating, nickel plating, da sauransu don inganta juriyar lalacewa da juriyar lalata. Zaɓin abubuwan rufewa shima yana da mahimmanci, yawanci ta yin amfani da babban aiki na roba ko hatimin ƙarfe don tabbatar da tasirin hatimi mai kyau.

1.4 Abubuwan da aka haɗa diaphragm

Bangaren diaphragm wani muhimmin sashi ne na kwampreso na diaphragm, wanda ke keɓance gurɓataccen iskar gas daga man mai da injin tuƙi, yana tabbatar da tsabtar gas ɗin da aka matsa. Abubuwan da aka gyara na diaphragm yawanci suna kunshe da zanen diaphragm, trays na diaphragm, faranti na matsa lamba na diaphragm, da sauransu. Gabaɗaya zanen gadon diaphragm ana yin su ne da ƙarfe mai ƙarfi ko kayan roba, waɗanda ke da kyakyawan ƙarfi da juriya na lalata.

Misali, farantin karfe na diaphragm yawanci ana yin su ne da kayan aiki irin su bakin karfe da gami da titanium, kuma ana sarrafa su ta hanyar fasaha na musamman don samun ƙarfi da juriya na lalata. Ana yin diaphragm na roba da kayan roba na musamman na roba, wanda ke da kyaun elasticity da abubuwan rufewa. Ana amfani da tire na diaphragm da farantin matsa lamba don gyara diaphragm, tabbatar da cewa diaphragm ba zai lalace ko karya yayin aiki ba.

1.5 Gas bawul da tsarin sanyaya

Bawul ɗin iskar gas wani sashi ne a cikin kwampreso na diaphragm wanda ke sarrafa iskar gas da fitar da iskar gas, kuma aikinsa kai tsaye yana shafar inganci da amincin kwampreso. Bawul ɗin iska yakan ɗauki bawul ɗin atomatik ko bawul ɗin tilastawa, kuma an zaɓa bisa ga matsa lamba na aiki da buƙatun kwarara na kwampreso. Ana amfani da tsarin sanyaya don rage zafin da aka yi ta hanyar kwampreso yayin aiki, yana tabbatar da aiki na yau da kullun.

Misali, bawuloli na atomatik yawanci suna amfani da bazara ko diaphragm azaman tushen bawul, wanda ke buɗewa da rufewa ta atomatik ta canje-canjen matsin iskar gas. Dole ne a sarrafa bawul ɗin da aka tilastawa ta hanyar hanyoyin tuki na waje, irin su na'urar lantarki, motsi na pneumatic, da dai sauransu. Tsarin sanyaya na iya zama mai sanyaya iska ko sanyaya ruwa, dangane da yanayin aiki da buƙatun kwampreso.

2. Aiki manufa na diaphragm kwampreso

Tsarin aiki na compressor diaphragm za a iya raba shi zuwa matakai uku: tsotsa, matsawa, da shayewa:

2.1 Matakin numfashi

Lokacin da piston ya motsa zuwa dama, matsa lamba a cikin Silinda yana raguwa, bawul ɗin ci yana buɗewa, kuma iskar gas na waje ya shiga jikin Silinda ta bututun ci. A wannan lokacin, farantin diaphragm yana lankwasa zuwa hagu a ƙarƙashin aikin matsa lamba a cikin silinda da matsa lamba a cikin ɗakin diaphragm, kuma ƙarar ɗakin diaphragm yana ƙaruwa, yana samar da tsari na tsotsa.

Misali, yayin aiwatar da inhalation, buɗewa da rufewa na bawul ɗin ci ana sarrafa su ta hanyar bambance-bambancen matsa lamba a ciki da wajen shingen Silinda. Lokacin da matsa lamba a cikin silinda ya fi ƙasa da matsa lamba na waje, bawul ɗin ci yana buɗewa ta atomatik kuma iskar gas ta waje ta shiga jikin Silinda; Lokacin da matsa lamba a cikin Silinda yayi daidai da matsa lamba na waje, bawul ɗin ci yana rufe ta atomatik kuma tsarin tsotsa ya ƙare.

2.2 Matakin matsawa

Lokacin da piston ya matsa zuwa hagu, matsa lamba a cikin silinda sannu a hankali yana ƙaruwa, bawul ɗin ci yana rufe, kuma bawul ɗin shayewa ya kasance a rufe. A wannan lokaci, farantin diaphragm yana lankwasa zuwa dama a ƙarƙashin matsa lamba a cikin silinda, yana rage girman ɗakin diaphragm kuma yana matsawa gas. Yayin da piston ya ci gaba da motsawa, matsa lamba a cikin silinda yana ƙaruwa akai-akai har sai ya kai saitin matsa lamba.

Misali, a lokacin matsawa, lanƙwasawa nakasar diaphragm an ƙaddara ta hanyar bambanci tsakanin matsa lamba a cikin silinda da matsa lamba a cikin ɗakin diaphragm. Lokacin da matsa lamba a cikin silinda ya fi ƙarfin da ke cikin ɗakin diaphragm, farantin diaphragm yana lankwasa zuwa dama, yana matsawa gas; Lokacin da matsa lamba a cikin silinda yayi daidai da matsa lamba a cikin ɗakin diaphragm, diaphragm yana cikin daidaito kuma tsarin matsawa ya ƙare.

3.3 Matakin shanyewa

Lokacin da matsa lamba a cikin Silinda ya kai saitin matsa lamba, bawul ɗin shayewa yana buɗewa kuma ana fitar da iskar gas ɗin da aka matsa daga silinda ta bututun shaye. A wannan lokaci, farantin diaphragm yana lankwasa zuwa hagu a ƙarƙashin matsa lamba a cikin silinda da ɗakin diaphragm, yana ƙara ƙarar ɗakin diaphragm kuma yana shirya tsarin tsotsa na gaba.

Alal misali, a lokacin aikin shaye-shaye, buɗewa da rufewa na bututun fitarwa ana sarrafa su ta hanyar bambanci tsakanin matsa lamba a cikin silinda da matsa lamba a cikin bututun fitarwa. Lokacin da matsa lamba a cikin silinda ya fi ƙarfin da ke cikin bututun shayewa, bawul ɗin shayewa yana buɗewa ta atomatik kuma an fitar da iskar gas daga jikin Silinda; Lokacin da matsa lamba a cikin Silinda yayi daidai da matsa lamba a cikin bututun shayewa, bututun da ke rufewa ta atomatik yana ƙarewa.

3. Halaye da aikace-aikace na diaphragm Compressors

3.1 Halaye

Babban tsaftar iskar gas: Saboda diaphragm da ke raba gas ɗin da aka matsa daga man mai da injin tuƙi, matsewar iskar gas ɗin ba ta gurɓata ta hanyar shafa mai da ƙazanta ba, yana haifar da tsafta mai yawa.

Kyakkyawan hatimi: Kwamfuta na diaphragm yana ɗaukar tsari na musamman na hatimi, wanda zai iya hana zubar da iskar gas yadda ya kamata, tabbatar da ingancin matsi da aminci.

Aiki mai laushi: A lokacin aikin aiki na kwampreshin diaphragm, saurin motsi na piston yana da ɗan ƙaramin ƙarfi, kuma babu wani hulɗa kai tsaye tsakanin sassan ƙarfe, don haka aikin yana da santsi kuma ƙarar ta ragu.

Karfin daidaitawa: Kwamfutoci na diaphragm na iya daidaitawa da buƙatun matsawar iskar gas daban-daban, gami da babban matsa lamba, tsafta mai ƙarfi, mai ƙonewa da iskar gas na musamman masu fashewa.

3.2 Aikace-aikace

Masana'antar Petrochemical: ana amfani da su don damfara iskar gas kamar hydrogen, nitrogen, iskar gas, da sauransu, suna ba da albarkatun kasa da ƙarfi don samar da sinadarai.

Masana'antar Abinci da Magunguna: ana amfani da su don damfara iskar gas kamar iska da nitrogen, samar da yanayi mai tsabta don sarrafa abinci da samar da magunguna.

Masana'antar semiconductor na lantarki: ana amfani da su don damfara iskar gas mai tsabta kamar nitrogen, hydrogen, helium, da sauransu, suna samar da yanayi mai tsafta don masana'antar guntu lantarki da samar da semiconductor.

A fagen gwaje-gwajen bincike na kimiyya, ana amfani da shi don danne iskar gas daban-daban na musamman da samar da tsayayyen iskar gas don gwaje-gwajen binciken kimiyya.

A takaice dai, compressors diaphragm suna taka muhimmiyar rawa a fannoni da yawa saboda tsarin su na musamman da ka'idar aiki. Fahimtar ka'idar aiki na compressors diaphragm na iya taimakawa wajen yin amfani da kyau da kuma kula da wannan kayan aiki, inganta ingantaccen aiki da amincinsa.

Lokacin aikawa: Satumba-12-2024